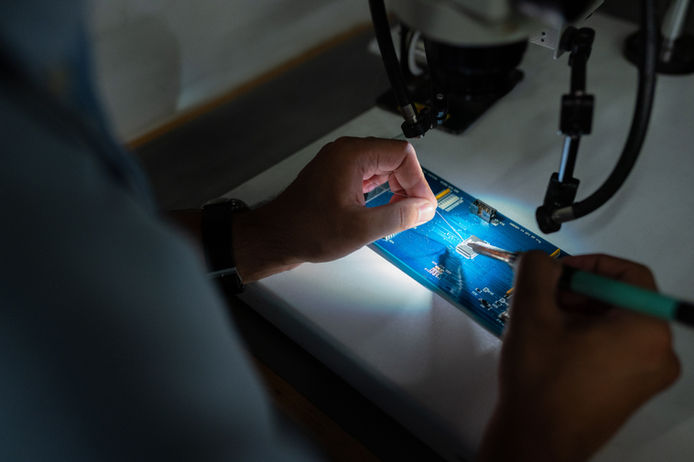

At BD Prototypes, all electronic and firmware engineering is handled entirely in-house so you benefit from seamless innovation, tighter integration, and unrivalled quality. Whether it’s detailed PCB and circuit design, embedded systems & firmware, or electro-mechanical integration, we work across the full product development lifecycle, from feasibility studies and concept through to prototype, enclosure design, and small-batch production.

Electronics Hardware Design

We provide end-to-end hardware design, from proof-of-concept boards to schematics, PCB layout, and BOM creation, ensuring robust and reliable electronic performance.

Electronics Testing & Certification

We apply rigorous testing to ensure every component meets the highest standards of durability, functionality, and safety, while achieving compliance with industry standards such as UKAS & CE.

Software & Firmware

Software and firmware are integral to modern product design, and we have invested in in-house expertise to accelerate development and deliver reliable, high-performance solutions for our clients.

Electro-Mechanical Integration

Harmonising electronics with mechanical elements, such as integrating electronics into your existing products (sensors, LCD screen, etc)

Custom PCB Design & Manufacturing

We deliver tailored PCB solutions from schematic and layout through to assembled boards. Our designs balance performance, size, power efficiency, and cost, ensuring reliable, production-ready PCBs that integrate seamlessly with enclosures and firmware, from prototypes to full production runs.

App Integrated Devices

Our team develops electronic devices that integrate with mobile apps to deliver smart, user-friendly experiences. Using Bluetooth Low Energy (BLE) and custom firmware, we design not only the hardware but also the companion app. Past projects include the YKK® Smart Zipper, where we designed the electronics and the app integration to showcase truly interactive technology.

FAQ – PCB Design Service UK

1. What sectors do you cover for PCB design services?

We provide PCB layout and engineering services across a wide range of industries, including aerospace, medical and healthcare devices, automotive, telecommunications, IoT, industrial, renewable energy, and oil and gas. Our team is familiar with ISO standards such as ISO 9001 and ISO 13485, as well as industry-specific standards for the oil and gas sector, including ATEX, IECEx, and API requirements. This ensures our designs meet the stringent safety, reliability, and environmental standards demanded in hazardous and high-performance applications.

2. Does BD Prototypes only offer PCB design? Or can you also assist with PCB manufacturing and PCB case design?

We provide end-to-end PCB solutions. Beyond design, we can handle prototyping and manufacturing to help you move smoothly from concept to production. Our team also offers custom PCB enclosure and case design, with in-house 3D printing available for rapid prototyping and fit testing before final production.

3. Will you use my CAD software package for design?

Yes, our engineers are familiar with popular CAD tools such as Altium, OrCAD, KiCad and more, so we can work with your preferred CAD format.

4. How long does it take to complete the PCB design?

The timeline will vary depending on the complexity of the design. We can deliver simple boards in a matter of days and complex multi-layer PCBs in a few weeks. We always provide an estimate of the total duration before starting.

5. What do I receive at the end of the design process?

You’ll receive a complete design package ready for immediate production, including schematics, Gerber files, the full Bill of Materials (BOM), assembly drawings, fabrication data, and DFM/DFA reports.

All associated intellectual property (IP) — including design files, source data, and documentation — is fully transferred to you upon project completion, giving you complete ownership and control of your design.

Where required, we can also manage the manufacturing process, ensuring a smooth transition from design to production with consistent quality and reliable delivery.

6. Can I get your team to review and optimise an existing PCB design?

Yes, we offer design checks on existing PCB layouts. We can do design audits, DFM/EMC checks and layout optimisations to improve the performance and manufacturability of the board.